9001cc以诚为本产品Products联系方式

地址:广州市番禺区大石街会江石北工业路644号巨大产业园15栋104

邮编:511430 电话:020-34796825、84781824 邮箱: kennyway@gzkennyway.com 联系人:13924296881 刘先生

13242771994 林小姐

|

电商详情

当前位置:

首页>

电商详情

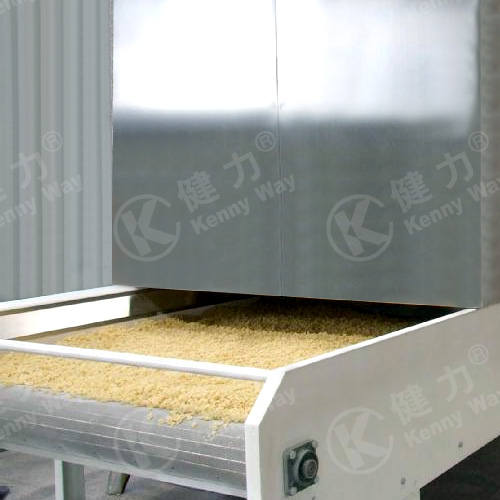

The Short Goods of Macaroni processed by KR6 Production Line may serve for instant soup rice vermicelli as well as stir-fried rice vermicelli. The products can also be fried and has a special flavor. There are two kinds of processing technology of Short Goods of Macaroni Production Line which makes the charateristics of products different as well. 产品留言 |